How Are Cashews Harvested? How to Harvest Cashews? How do harvest raw cashews in Vietnam? Cashew Harvesting? Cashew Tree is usually only grown in the southern provinces of Vietnam, especially in the Central Highlands, Southeast, and has a few in the West. Currently, the provinces with the largest cashew growing areas include Binh Phuoc, Dong Nai, Dak Lak, Binh Thuan, and Binh Dinh. The Cashew harvest season in Binh Phuoc Vietnam starts quite early, around the end of January or February, and ends in May or June depending on weather and planting methods. Cashew tree plants flower for 2 or 3 months and fruits mature about 2 months after the blooming. When the whole fruit is fully ripe, it falls to the ground, and harvesting generally involves collecting nuts when they have dropped.

=> More info here: What Difference Between Raw Cashew Nuts vs Cashew Kernels?

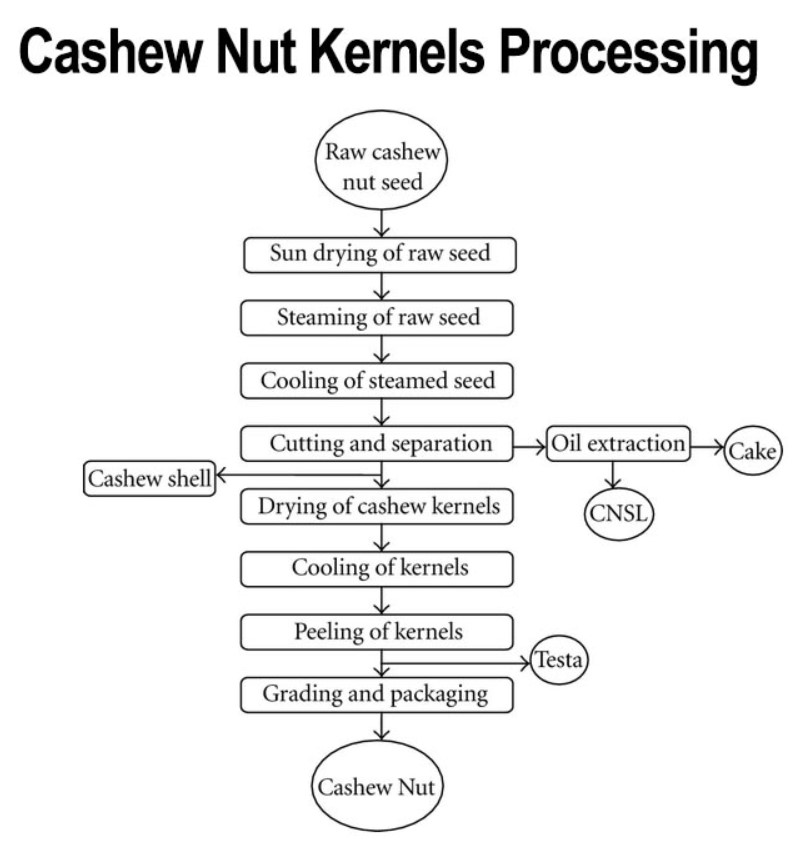

12 Steps To Harvest Cashew Nuts In Vietnam. Like other places, farmers in Vietnam also harvest cashew nuts following basic steps below – How Are Cashews Harvested:

- Step 1: Collected Cashews Waiting For Cashew Fruits to Fall.

- Step 2: Separating The Cashew Nuts

- Step 3: Sun-Dry Raw Cashew Nuts

- Step 4: Storage of Raw Cashew Nuts

- Step 5: Steaming Raw Cashew Nuts

- Step 6: Hard Shell Cutting

- Step 7: Drying Cashew Nut Kernels

- Step 8: Peeling The Testa

- Step 9: Color Sorting Cashew Nut Kernels & Quality Control Cashew Nut

- Step 10: Metal Detectors

- Step 11: Packaging & Shipping

- Step 12: Fumigation Before Ship

@Read More: Vietnam Cashew Harvest Season

Producing Process Vietnam Raw Cashew Nut to Cashew Kernels – How Are Cashews Harvested

How are cashews harvested – Like other places, farmers in Vietnam also harvest cashew nuts following the 12 basic steps – Kimmy Farm Vietnam

Step 1: Collect Cashew Fruits

Waiting For Cashew Fruits to Fall – Harvesting cashews Vietnamese farmers wait for the fruits to fall into groups and then collect them. If you pluck the cashew fruits with your hands before cashews get fully matured, they will reduce the quality of the cashew nuts. While waiting, they keep the area below the cashew trees well-raked and clear of weeds. Daily collection of raw cashew nuts & cashew fruits from the ground. Collecting cashew nuts from the ground usually every 2 to 3 days if the weather is favorable. If the weather is not favorable, the quality of the fruit will be reduced, so we need to increase the frequency of harvesting.

=> Related article: What Is The Difference Between Raw Cashew Nuts And Cashew Kernels?

The Cashew fruits Fell to the ground, waiting for the collector – The cashew nuts are early season in Vietnam – Kimmy Farm Vietnam

Step 2: Separating The Raw Cashew Nuts

Vietnam’s Cashew Farmer collection of raw cashew nuts

The quality of the nut will be affected when the apple is not neatly detached from the nut.

Step 3: Sun-Dry Raw Cashew Nuts

Local Famer drying the raw cashew nut after collecting them. – Kimmy Farm Vietnam

Step 4: Storage of Raw Cashew Nuts

Dried raw cashew nuts must be stored in jute bags where they get more air ventilation.

Kimmy Farm Raw Cashew Nuts Warehouse

Step 5: Steaming Raw Cashew Nuts

The steaming of raw cashew nuts prior to shelling is adopted widely in medium-scale cashew nut processing mills with the help of a boiler. The steaming of raw cashew seeds is carried out by the indirect or direct method of boiling. The indirect method includes the steaming of cashew seeds in a separate cooker, while the direct method includes the placing of cashew seeds at the same place at which water is boiling. The process of steam roasting helps remove this hardshell with minimal effort. These cashew nuts are left in the drum for 20 minutes for proper roasting. The roasted cashew nuts are then taken out of the drum and placed in the open air for around 12 hours to let them cool down and help remove the cashew shells. The boilers used for the generation of steam are of various capacities depending upon the need of any processing unit, which consumes electricity and biomass as a fuel.

=> Related article: Cashew Shells Vietnam High Quality For Export

Step 6: Hard Shell Cutting

The raw cashew nuts are delivered to the factory to prepare them for cutting shells (hardshell outside – cashew shell) and peeling husk skin. Firstly, after steaming to de-acidify the cashew shell. This process helps to soften the hardshell of cashew nuts. After Steam Roasting is complete, the cashew nuts are cut off by specialized knives to remove the outer shell to get the inner kernel. This is a very difficult stage, requiring skilled workers to separate the shell without breaking the inner core of the cashew nuts (cashew kernel). Usually, the cashew shells will be thrown away like waste, but now they are used to make many useful products. Today, in large factories, people cut cashews by machine.

=> Check Out! The Product from Cashew Shell: https://kimmyfarm.com/en/vietnam-cashew-nuts/shell

Cashew Shell cutting difficult stage, requiring skilled workers to separate the shell without breaking the inner core of the cashew nuts kernel.

Step 7: Drying Cashew Nut Kernels

In order to keep the cashew nut long time, we can make dried under the sun or use the drying machines. The moisture is 3-5% suitable with export standards and keeps it longer. Besides It also removes the testa of cashew nuts easier.

The moisture is 3-5% suitable with export standards and keeps it longer. Besides It also removes the testa of cashew nuts easier. – Kimmy Farm Vietnam

Step 8: Peeling The Testa

The inner shell of the kernels has to be removed to produce the white nuts. The peeling process is designed to remove this inner softshell after the cashew kernel is removed from the oven. The cashew kernel is used for peeling after it is left in the open for a period of 12 hours. This cooling helps in the peeling process. Each nut is individually peeled to get white nuts. These white nuts are then sent to the grading department.

Peeled Testa Cashew Nut Machine – The inner shell of the kernels has to be removed to produce the white nut.

Step 9: Color Sorting Cashew Nut Kernels & Quality Control Cashew Nut

The process of grading is designed to sort the white cashew kernel into different grades. The white kernel is divided into two main types wholes and pieces. The process of sorting wholes and the pieces are based on the size, color, and texture of the nuts. The sorting is done based on the set international sizes (AFI Standard For Cashew).

=> Related article:

- How To Check Quality Of Cashew Nut Kernels?

- Different Grades Of Cashew Kernel, Cashew Grade List Vietnam

Color Sorting Cashew Nut Kernels & Quality Control Cashew Nut kernels – Kimmy Farm Vietnam

Step 10: Metal Detectors

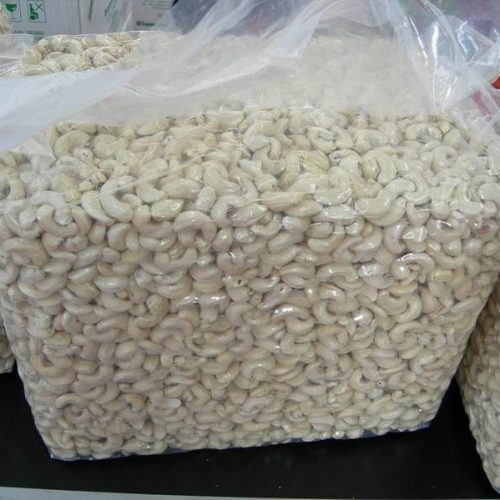

Cashew kernels before packing; must be checked through metal detectors to remove impurities. The cashew kernels are packed into plastic bags of 22.68 kg of different sizes for sale in the local market and in tins of 11.34 kg for sending to others.

Metal Detectors & Packaging – The cashew kernels are packed into plastic bags of 22.68 kg of different sizes for sale in the local market and in tins of 11.34 kg for sending to others.

Step 11: Packaging & Shipping

There are 4 ways to pack cashews nuts:

- Option 1: Packing Cashews by PP Bag with 22.68kg/1 bag! and 1 Bag in 1 Carton! (700 cartons, 1 container 20ft).

- Option 2: Packing Cashews by PP Bag with 11.34kg/1 bag! 2 Bags in 1 Carton! (700 cartons, 1 container 20ft).

- Option 3: Packing Cashew Nuts by Tin Box with 11.34kg/1 tin-can! 2 tin can in 1 Carton!! (700 cartons, 1 container 20ft).

- Option 4: Packing according to customers ordering. Discuss more details when ordering.

Cashew nut kernels can be transported by ship, container ship, truck, or railroad… cashew kernels are predominantly shipped in containers with a favorable travel temperature range: of 5 – 25°C. In weather (rain, snow…), the cargo must be protected from moisture, since it may lead to mold, spoilage, and self-heating as a result of increased respiratory activity. Hooks shouldn’t be used with bagged cargo, so as to prevent damage to the bags and loss of volume.

Packing Cashews by PP Bag with 11.34kg/ 1 bag, 2 bags in 1 carton.

Packing Cashews by PP Bag with 22.68kg/ 1 bag! and 1 bag in 1 carton!

Packing Cashew Nuts by Tin Box with 11.34kg/ 2 tin can in 1 Carton

2 tin cans in 1 Carton – Cashew Kernels Vietnam

Shipping For Small Orders

- Shipment: By courier company, such as EMS, DHL, FedEx, and TNT

- Delivery Time: Within 4-10 working days after the goods ready for shipment

For Small Order: Shipment By courier company, such as EMS, DHL, FedEx, TNT… and Delivery Time Within 4-10 working days after the goods ready for shipment

Shipping For Bulk Orders

- Shipment: By sea (LCL, FCL) or by air (according to buyer’s request)

- Delivery Time: Within 15 – 30 working days after the goods ready for shipment

For Bulk Order Shipment By sea (LCL, FCL) or by air (according to buyer’s request) Delivery Time Within 15 – 30 working days after the goods ready for shipment

Step 12: Fumigation

At this stage, because nuts are food items that require very strict sewn food safety. Fumigation is the process of using chemical smoke to kill pests like insects or rodents. Therefore, the purpose of fumigation stitching is to clean, disinfect and eliminate pathogens. We use cleaning and disinfection cashew nuts machines for reducing or eliminating pathogens, bacteria, and other sources of disease.

@More Info about Vietnam Cashew Nuts!

A brand specializing in the production and export of agricultural products in Vietnam. We have a black soldier fly farm in Tay Ninh and a cashew growing area in Binh Phuoc. The main export products of the company are: cashew nuts, cashew nut kernels, black soldier fly, frozen seafood, shrimp, prawns, catfish… from Vietnam.